A bean to bar chocolatier

Responsible and rigorous sourcing for exceptional couverture chocolate

Responsible and rigorous sourcing for exceptional couverture chocolate

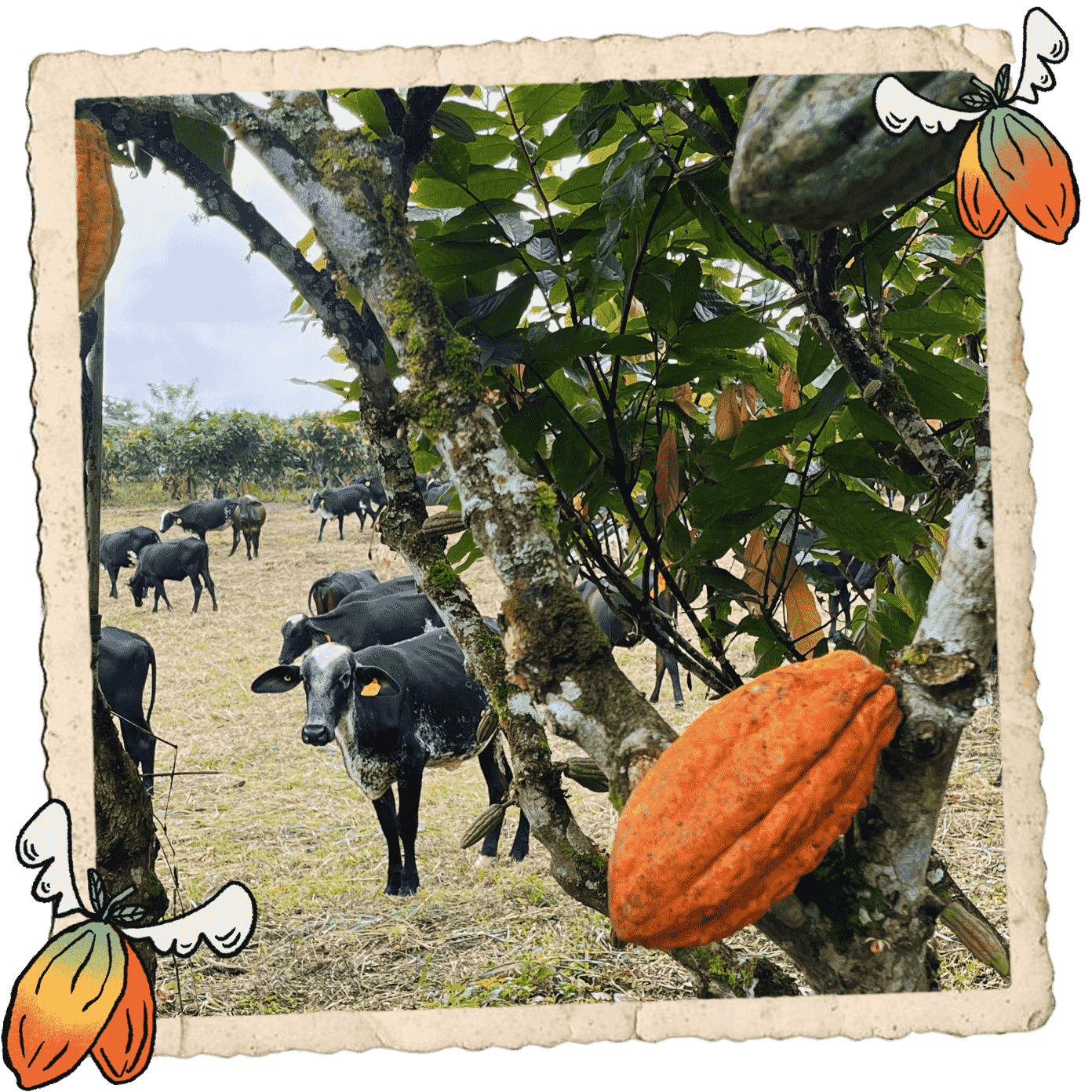

One of the key ingredients used by the chocolatiers, who work alongside the Dolfi family, to create their delicious couverture chocolate, is cocoa. This chocolate-obsessed family, maintains direct contact with a selection of hand-picked farmers, visiting them in the field, in Ecuador or Madagascar, ensuring that the beans are grown in accordance with precise specifications, both in terms of quality and social conditions. So, the company decides on everything from its “single origin” recipes made with beans from different regions – each with its own distinct flavour – such as Haïti, Madagascar, Sao Tomé, Ecuador and Peru, to cocoa bean blends.

Close relationships with producers

Close relationships with producers

We constantly aim to improve the quality of our products and build deeper relationships with farmers, which is why we prioritise, and try to develop, direct supply chains to source our cocoa beans and dried fruit. We go into the field to identify partners with whom we work closely, most of whom have been with us for years.

In this way, we can check that we share the same values, that the farmers are working in good conditions, that the plantations are well maintained and that the entire process – from the harvesting to the drying of beans – is carried out with the utmost care, resulting in distinctive, flavourful cocoa beans.

Our approach to the sourcing and selecting of raw materials, namely cocoa beans, is the area in which we have most evolved. Because we want to distribute our profits fairly, particularly when it come to the farmers, we buy our cocoa beans directly from local cooperatives in, for example, Haiti, Madagascar or Peru. This approach also allows us to maintain full control of our product, ensuring excellent quality.

A journey through the cocoa plantations

A journey through the cocoa plantations

Tours factory and the importance of preserving local expertise and know-how

Tours factory and the importance of preserving local expertise and know-how

The cocoa is processed, praline prepared, and chocolate bonbons produced in our large factory, fitted with traditional and high-tech equipment, using a clever blend of innovative and traditional techniques, with final products then dispatched to be sold in our shops. Some techniques, such as scraping vanilla beans and filling novelty Easter chocolates are highly technical and require traditional skills. As such, they can only – and will always – be done by hand, rather than machines, something that is unusual in the luxury food world, where many activities are outsourced.

This culture of sourcing and selecting high quality products, which has been a hallmark of our company for more than 20 years, is best illustrated by our praline, which we make ourselves, from start to finish. The mixture contains French hazelnuts, almonds and pistachios from Sicily, and dried fruit, all of which are carefully and lovingly selected. The fruit and nuts are roasted, caramelized and crushed by hammer at the family factory in Chambray-les-Tours, near Tours, and then processed in a one-hundred-year-old mill before being turned into amazing praline used to make chocolate bonbons.

We make our own couverture chocolate, using a blend of high-quality cocoa-beans which lends it its unique character. Other chocolatiers will often use the same supplier and so end up with the same flavours. In today’s sugar-demonizing climate, we have made it our mission to promote and share the true taste of good chocolate.

The House

A family business

It all starts with a passion, that of Etienne – a great lover of sweets and…

EXPÉDITION FRANCE MÉTROPOLITAINE

Jeux de Paris 2024 : Pendant la période des Jeux Olympiques du 18/07 au 11/08/2024 et selon les décisions prises par les autorités, des restrictions de circulation s’appliqueront dans les 1er, 4ème, 5ème, 6ème, 7ème, 8ème, 15ème, et 16ème arrondissements de Paris, ainsi que ceux de Saint Denis (93200), La Plaine-Saint Denis (93210), Ile de Saint Denis (93450) et le Bourget (93350). Dans ces conditions, le trafic sera fortement perturbé et les délais de livraison rallongés.

- Colissmo minimum 48h – 10€

- Chronopost minimum 24h – 13€

- Chronofresh minimum 24h – 15€

Nous adaptons la température de transport à la saison ! Avec la livraison Chronofrais, vos produits sont transportés dans le plus strict respect de la chaîne du froid, entre 0°C et 4°C.

Toute commande passée après 14h30 partira le lendemain.

Si vous commandez un vendredi soir, un samedi ou un dimanche, votre commande partira le lundi.

Un numéro de suivi vous est communiqué par mail à la suite de votre commande. Attention, ces mails finissent parfois dans les courriers indésirables.

Une fois votre numéro de suivi retrouvé vous pourrez suivre votre colis sur le site de Chronopost.fr ou laposte.fr

COURSIER PARIS ET PROCHE BANLIEUE

Jeux de Paris 2024 : notre service coursier Paris et proche banlieue s’adapte aux perturbations des JO. Le trafic sera fortement perturbé et les délais de livraison rallongés. Tarifs exceptionnels du 01/07 au 15/09 inclus.

Paris (24€) et proche banlieue (44€) le jour même en 4h ou programmée le jour de votre choix sur un créneau de 3h du lundi au vendredi pour toute commande passée avant 16h*.

Toutes commandes passées après 16h sont traitées dès le lendemain matin.

Plus de détails de nos modes de livraison ici.

Nos assortiments sont composés de chocolat noir, chocolat au lait et chocolat blanc, de manière aléatoire.